Imagine electronics that disappear after use, with virtually no waste. Scientists at the University of Maryland have developed innovative 3D-printed electronic boards that dissolve in water, opening up new possibilities for rapid prototyping and easier recycling.

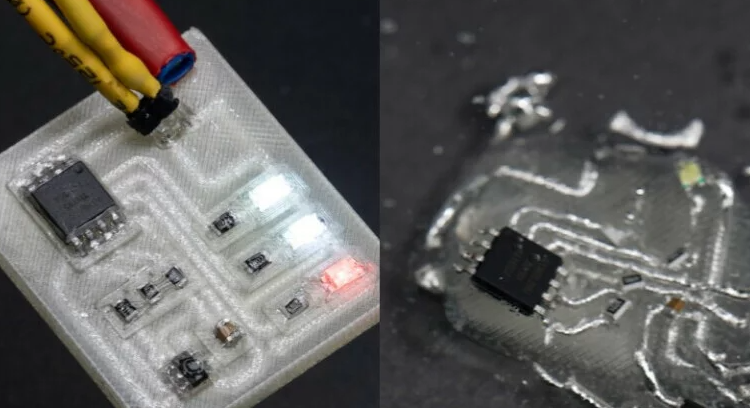

The research team, led by Huaishu Peng, used polyvinyl alcohol (PVA), a synthetic polymer that dissolves in water, as the base material for the boards. They created the wiring by injecting an alloy of gallium and indium into specially designed channels, while the electronic components were placed by hand and fixed with a polymer adhesive. After drying at 60°C, the boards were ready to use.

As a proof of concept, functional devices such as a Bluetooth speaker, a fidget toy, and a robotic gripper were created. While small amounts of water do not harm the devices, after 36 hours in water at room temperature, the boards completely dissolved. The team was able to recover almost all of the polyvinyl alcohol and most of the metals, indicating great potential for sustainable recycling and reuse of the material.

Experts point out that printed circuit boards are a major source of electronic waste, and traditional recycling methods are often inefficient. According to a 2022 United Nations report, Asia produced 600,000 tons of discarded circuit boards, but recycled only 17%, while Europe and North America had significantly better results, with 61% and 44% of circuit boards recycled, respectively.

This technology brings a new perspective: 3D printers allow anyone to quickly create temporary electronic circuits that are easily dissolved after use. Researchers are also considering the use of waterproof housings to extend the life of the devices.

Peng points out that this approach can greatly reduce the time it takes to produce prototypes. Instead of weeks of processes in factories, new circuits can be printed in 30 minutes, and if they don’t work, they can be melted down and the materials reused.

This innovation promises to significantly reduce electronic waste and is open to collaboration with manufacturers for mass production in the future.